Issues & Solutions

Go more in depth on common issues that impact wastewater management. These links will take you to the TeamAquafix USA site. All products used to address these issues are available in Canada. If you do reach out to the American team, you will be connected to our team in Canada to assist you.

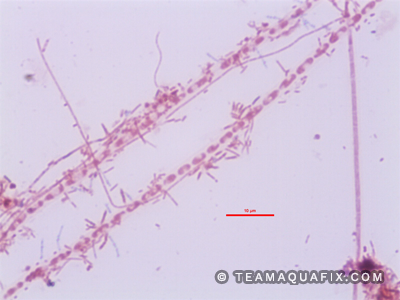

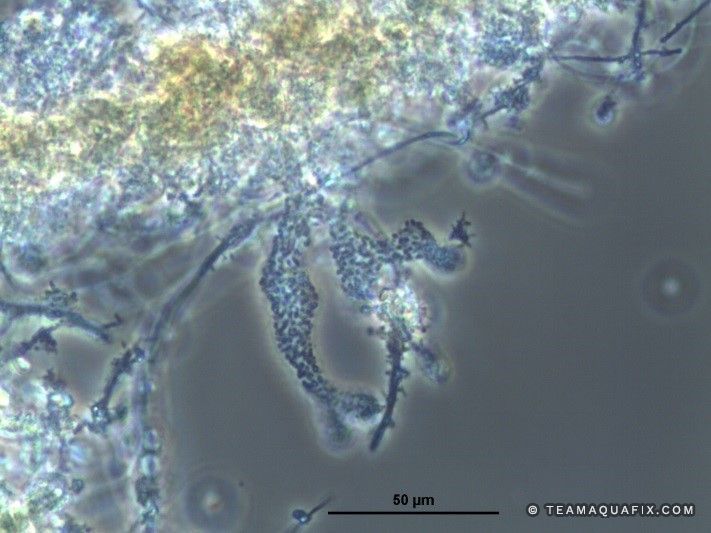

Foaming Filaments

Common Filaments in Wastewater

Filaments contribute to bulking and often to foaming. If you’re experiencing either of these problems we can assist with sampling and lab work to identify exactly what is causing the issue. Call 1-888-466-0031 and we’ll get the appropriate test collection kit sent to you promptly.

Red Worms & Midge Flies

The red worm and midge fly lifecycle can thrive in the nutrient rich conditions of a wastewater lagoon. This can deplete bacteria and negatively impact multiple factors of lagoon performance. If you have an established midge fly infestation every 10 days the life cycle restarts. Our effective larvacide can also have other products mixed in to address the unique challenge of dealing with midge flies in a system that has a lot of grease.

Lagoon Management

Odour Control in Lagoons

Lagoon dredging is costly. Effective sludge management via enhanced biological processes is a long-term, cyclical savings approach. Not only do managers save on dredging costs, they have more predictable effluent discharge. The Vita-Stim line up of products is specifically designed to work in facultative, aerated and anaerobic lagoon systems.

Lagoon Sludge Management

Lagoon dredging is costly. Effective sludge management via enhanced biological processes is a long-term, cyclical savings approach. Not only do managers save on dredging costs, they have more predictable effluent discharge. The Vita-Stim line up of products is specifically designed to work in facultative, aerated and anaerobic lagoon systems.

Fats Oils and Grease Management

Grease Control in Wastewater

Grease is a constant in the life of a wastewater system operator. People will not quit eating it, washing it down the drain, or disposing of it in ways they think won’t be noticed. We take an alternative approach to solvents to deal with grease by degrading it. We have a mix of approaches including enzymes (even for anaerobic digesters), bacteria and bio catalysts.

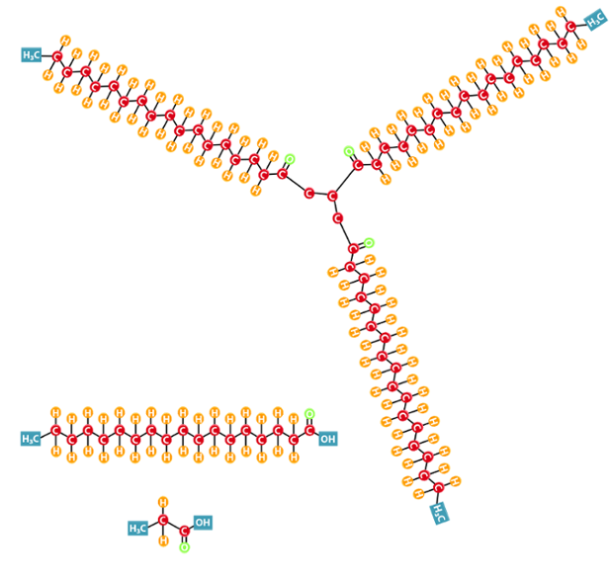

Long Chain Fatty Acids

A high percentage of the grease entering a wastewater system, at the molecular level, is long chain fatty acids(LCFA). This matters in wastewater management because LCFA resists traditional grease management strategies and products. It’s necessary to break the LCFA into simple molecular structures to allow bacteria and enzymes to properly degrade the grease. It’s important to break down LCFA because they are a primary nutrition source for filaments that cause foaming and bulking.

Settling and Understanding the Relationship between Zoogloea and EPS

Maintaining proper levels of extracellular polymeric substances (EPS) in wastewater treatment plants can play a major role to improve settling. High levels of EPS can easily cause bulking, foaming, and effluent violations, but these substances are also essential for good floc formation and to improve settling properties in wastewater treatment systems. Zoogloea is a genus of bacteria that are commonly known for excreting high levels of EPS in wastewater treatment systems. This page will cover the “what” and “how” of managing EPS and Zoogloea for effective wastewater treatment.

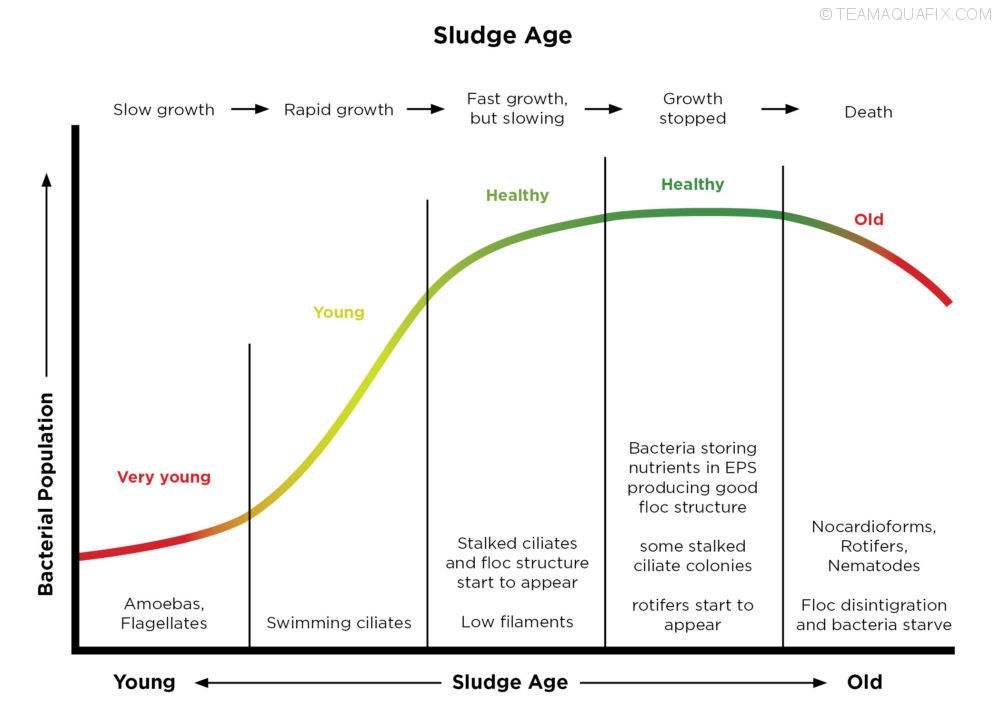

Food to Microorganism F:M Ratio

Optimizing the food supply for the bacteria in your wastewater system is one of the most effective ways to reduce the risk of upset. A thriving bacteria colony provides the operatore the time and warning needed to address issues as they develop. The age of the sludge in your system plays an important role in the ecosystem necessary for thriving bacteria. Click through for a simple calculator to help understand the relationship between F:M and determine when a little more food may be needed.

Anaerobic Digestion

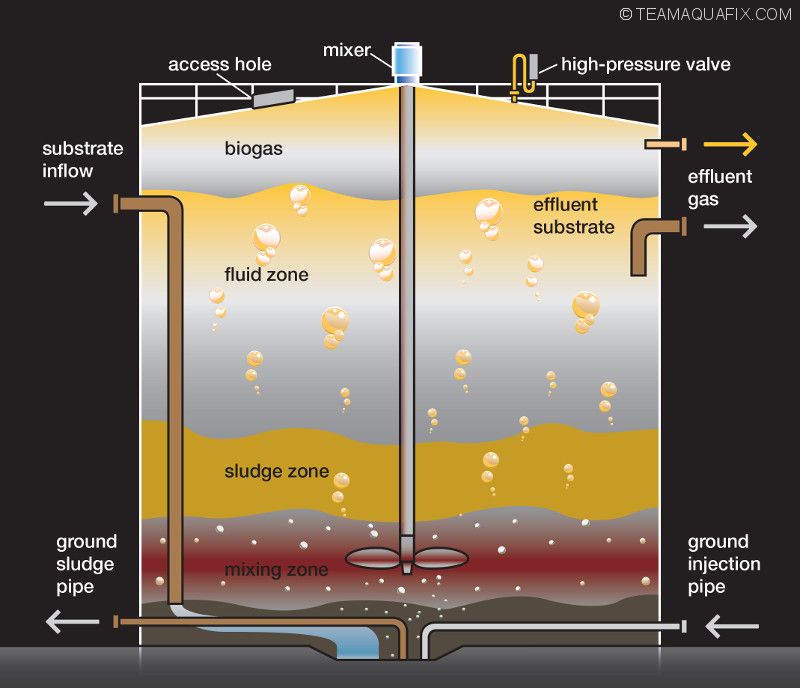

The Path to Consistent Successful Anaerobic Digestion

Anaerobic digestion has been a known idea for centuries, but it remains shrouded in mystery for far too many folks. The growing demand for biogas from these systems will only be met with system management that produces consistent, reliable outputs. Learn more about the fundamentals of anaerobic digestion and the role of bacteria.

Anaerobic Digesters and Safety – Introduction

Methane is combustible. Learn more about how to work safely with this gas in an anaerobic digester through proper design, maintenance and hazard management.

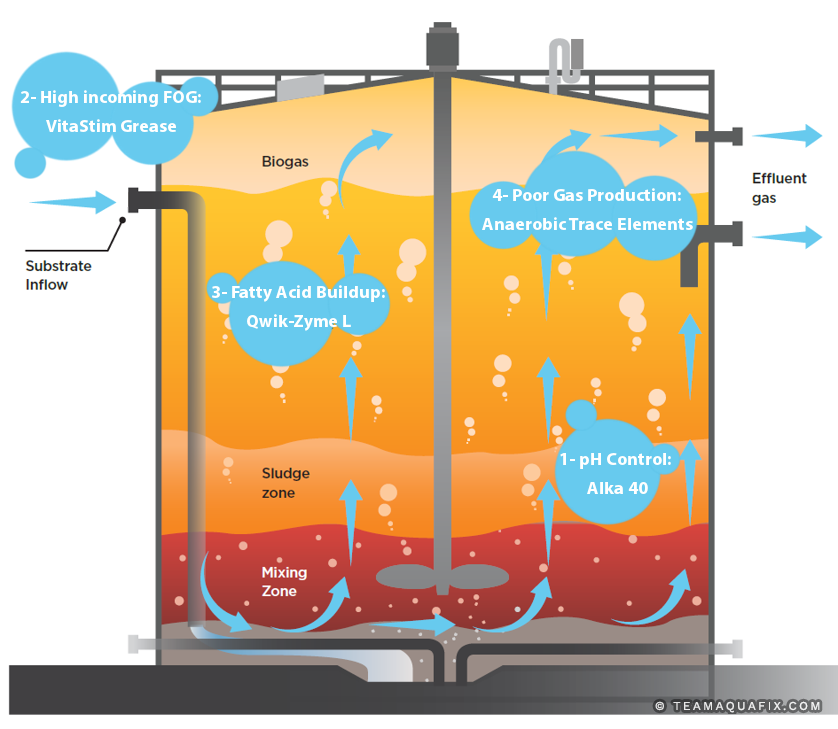

Troubleshooting in Anaerobic Digestion

The lure of anaerobic digestion is the promise of consistent biogas production. The fact is that the systems can be prone to upset without a solid understanding of what happens inside the tank and how to nip developing problems in the bud. This article looks at the fundamentals of operating conditions, alkalinity and pH, nutrition, toxicity, mixing and early diagnosis through observation.

Foaming in Anaerobic Digestion - How To Fix It

Foam is always present, but excess foam is one of the most common symptoms of an anaerobic digester upset. Combatting foam and resetting the system to optimum management and production relies on understanding the filaments that drive foam production in the anaerobic environment.

Toxicity

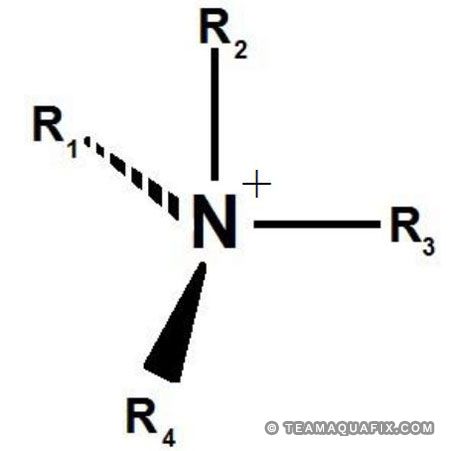

What the Quat?

Quaternary Ammonium Cation (QACs) Toxicity is a key concern of many operators. Understanding the role of QACs play in your wastewater system was a key area of study for Aquafix in 2017. The goal was to understand what level of QACs are necessary to cause system upset and how to recover quickly when this happens.

Hydrogen Sulfide

Wastewater Solutions for Hydrogen Sulfide (H2S)

Many people will recognize the rotten egg smell of H2S. This corrosive and poisonous gas is highly detrimental to wastewater systems. Sulfur is readily present in many different waste streams, including human and livestock waste. It’s not enough to mask odours or use oxygenation to remove it. There are options that directly deal with H2S through molecular binding and will reduce the corrosion and other wastewater system management costs that H2 incurs.