Description

Foam Buster is a blend of specialized proteins, free amino acids, and micronutrients which stimulate the floc-forming bacteria to degrade grease, emulsions, and helps them to outcompete the filaments which cause foaming. Chlorinating can only provide short term relief, and often only fragments the filaments, leading to worse foaming issues down the road. Foam Buster addresses the underlying cause of foaming.

Foaming filaments like Nocardia-like organisms and Microthrix parvicella use fatty acids to produce a buoyant cell wall. Foam Buster programs your wastewaters plant’s naturally occurring bacteria to consume these fatty acids. Foam Buster’s vitamins enable certain cellular functions to accomplish this task. Once the degradation of FOG and fatty acids improves, these troublesome filaments cannot survive on the dwindling food supply.

Foam Buster is effective in the oxidation ditches, activated sludge plants, SBRs, extended aeration wastewater treatment plants, and aerobic digesters. All these areas can be infiltrated by foam-causing, F.O.G.-hungry filaments like Microthrix parvicella, Nocardia, and Type 1863. Foam Buster also works well on the bulking filament Type 0092.

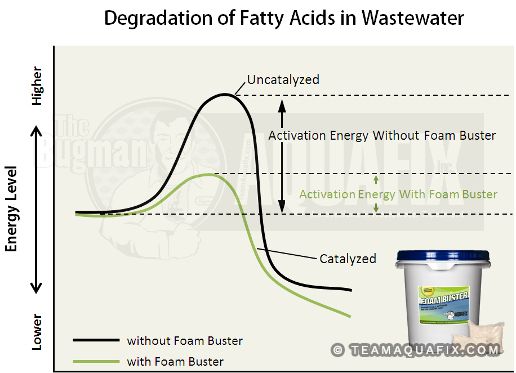

Most bacteria in wastewater plants are unmotivated and listless. Part of Foam Buster’s micronutrient blend is formulated to give the filament-degrading bacteria extra boosts of energy that allow them to degrade the filaments faster than they can reproduce thus getting rid of foam. As the graph shows, Foam  Buster allows wastewater bacteria to degrade filaments while contributing a much lower amount of their own energy.

Buster allows wastewater bacteria to degrade filaments while contributing a much lower amount of their own energy.

Foam Buster supports filament degradation in more ways than energy. Its formula also contains nutrients specifically needed by the bacteria to create certain foam-busting biocatalysts. A bacon grease molecule is different from a butter molecule is different from a filament molecule, and Foam Buster provides the right array of micronutrient ingredients to allow the bacteria to produce the specialized recipes for biocatalysts to attack these different molecules.

A lot of time when a wastewater plant gets foam they will use a chemical defoamer or an anti-foam to knock it down. Chemical defoamers work by covering up the problem for a period of time. In addition, chemical defoamers can cause sludge bulking issues, nitrifier toxicity, and are limited in that they do not control Nocardia or surfactant foams. Silica anti-foamers break down into siloxanes which corrode combustion engines. Neither type of product truly addresses the root cause of the problem.

Reviews

There are no reviews yet.