Description

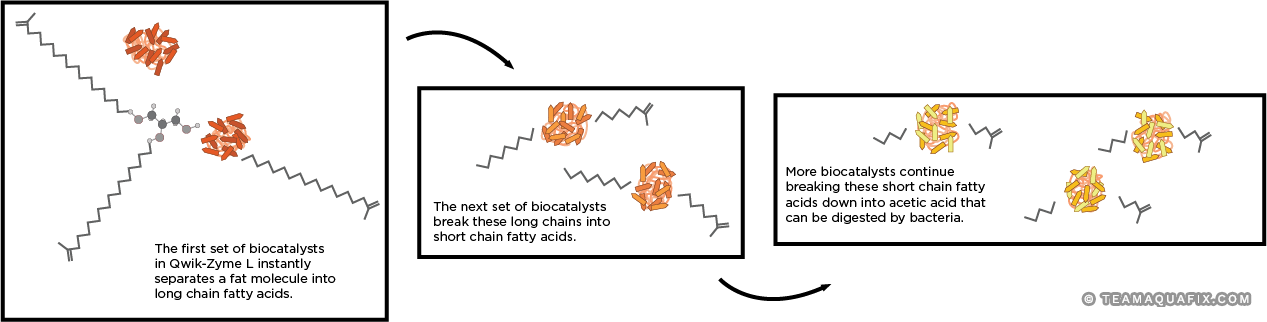

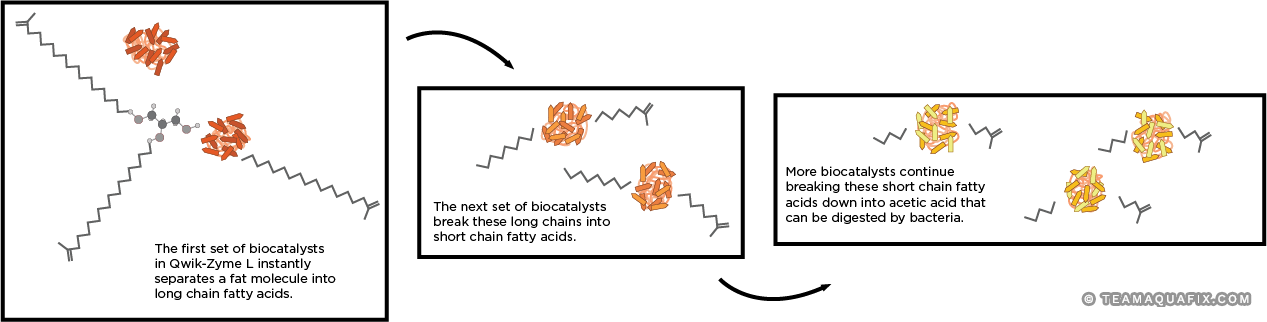

How it Works: Qwik-Zyme L incorporates three types of fat-degrading biocatalysts to provide dramatic hydrolysis of fat, oil, and grease (FOG). These catalysts speed the breakdown of complex fat molecules into simple short chain fatty acids, which can help lower phosphorus. These fatty acids are then taken up by filaments, like Microthrix parvicella and Nocardia, which allows them to float and foam. Qwik-Zyme L breaks up these fatty acids and cuts off the filament’s food source. When possible, increase wasting to lower sludge age during filament control treatment.

Qwik-Zyme L is an excellent grease degrader in sequencing batch reactors (SBR), wastewater treatment plants, equalization tanks, and food and egg processing plants.

What it Does: It can degrade a range of fatty acids such as oleic, steric, and palmitic as well as fish oils, triglycerides, milk, and animal fats. Qwik-Zyme L works best from pH 6-9 and from 45–140°F (8 to 60°C) and is formulated for aerobic treatment systems. For similar issues in anaerobic processes, see Ana-Zyme G.

Product Pairings

Add Foam Buster for a more complete foaming filament control.

Follow up with Bug On A Rope for ongoing maintenance after the lift station is cleaned up.

Case Studies

Challenge

High Lauric and Stearic Fatty Acids

Solution

Qwik-Zyme L, VitaStim Surfactants

Results

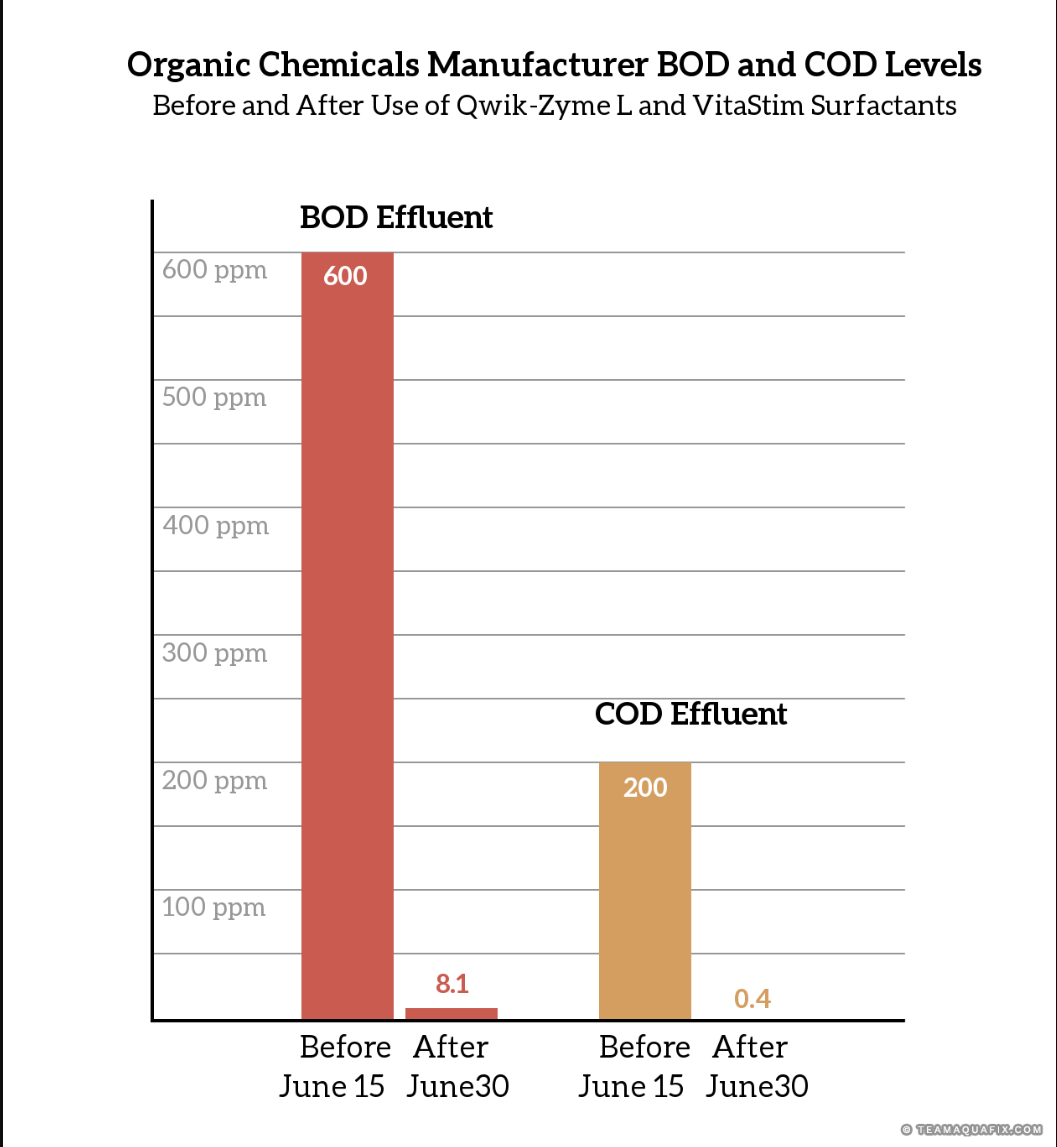

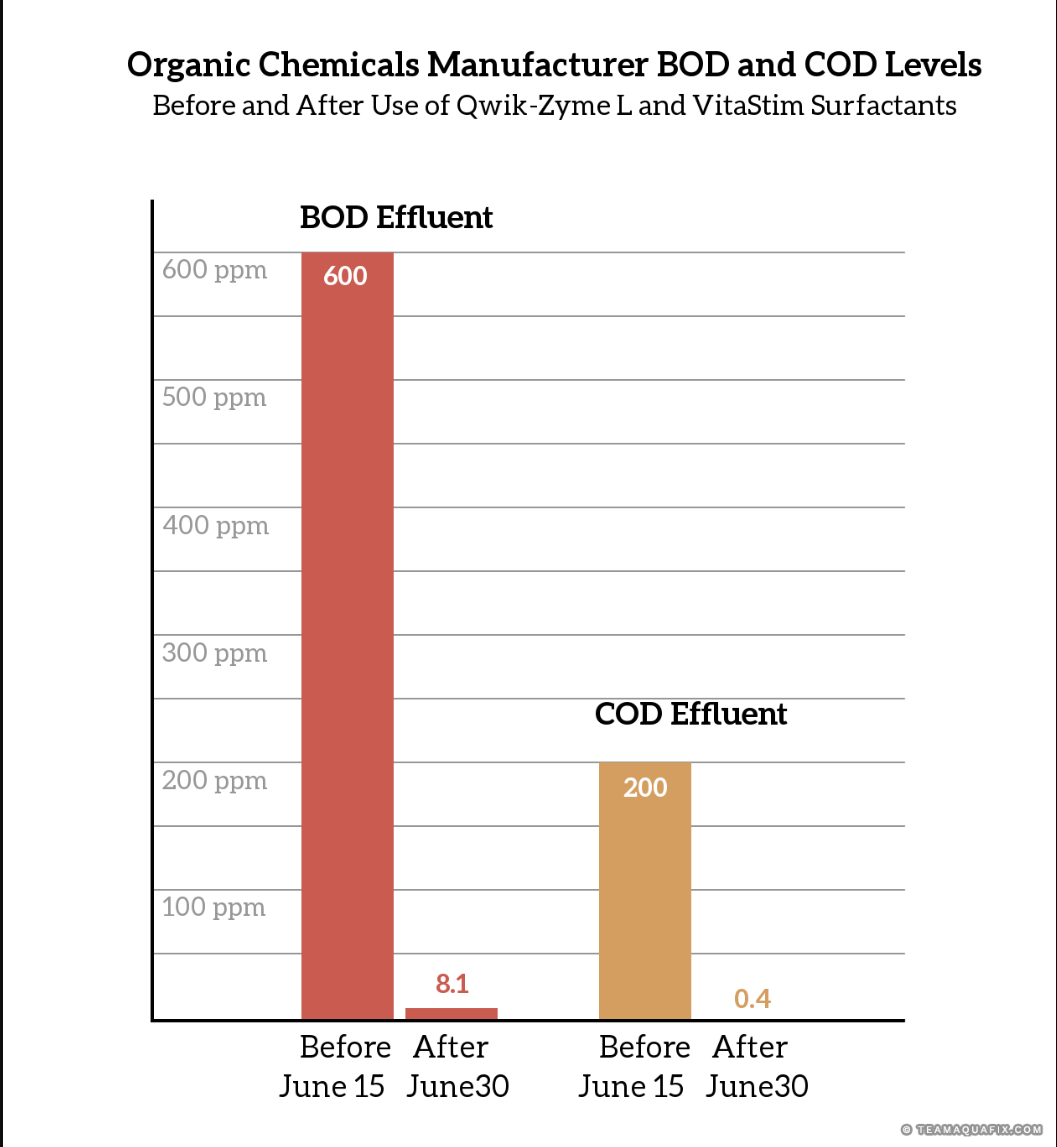

An organic chemical manufacturer in North Carolina contacted us about foam being generated in their treatment system. They use a series of two lagoons, with high aeration in the first lagoon to pretreat their waste stream before sending it to the municipal wastewater treatment plant. The waste stream has high concentrations of lauric and stearic acids which contribute to 600 ppm influent BOD and 200 ppm COD. The system was not achieving complete breakdown of these fatty acids as the waste stream moved quickly through the system. The operator began using VitaStim Surfactants to add new bacteria cultures which break-down fatty acids. This improvement was enough to make the customer happy, but we thought that adding our Qwik-Zyme L, a liquid biocatalyst product, would help break down the fatty acids even more quickly. The biocatalyst accelerated the process, which was a huge benefit in this waste stream with a short detention time. The combination of biocatalyst and bacteria brought the system’s effluent waste stream down to 8.1 ppm BOD and 0.4 ppm COD.

Village of Westfield (WI) –

Began using these two products (Foam Buster & Qwik-Zyme L) one month ago to help reduce nocardia. Though I still need to waste more at the plant, I am seeing a benefit in phosphorous reduction it appears based on data.

Josh L (CO) –

Quick-Zyme L, Smart BOD, and ReBuild have helped our plant recover and run great through start up and shock while jetting lines. Operation of two SBRs is needed to accommodate the volume of decant from the digester. We run on the low end of the F:M ratio and these products help with that also.

Ryan S (FL) –

Helps get control of bulking filaments fast. Easy to use and effective.